During the flood of 2019, the City Of Toronto Parks Department had dozens of gas pumps scattered across Toronto Island to combat the high water levels that threatened park land, businesses and a small community that calls the Island home.

Each pump served a critical purpose; it moved water out of areas often below the level of the lake, sending it over sandbag walls and back into the harbour. For months on end, the water went round and round in an effort to keep the low spots on the Island from washing out. On a number of occasions when the wind came from a critical direction, the houses along the shoreline experienced moments of being inundated with waves crashing over the walls and into their homes. There were times when strange ‘rogue waves’ or swells would all of a sudden raise the water level of the lake several inches and as much as a foot in a matter of minutes. The main roads across the island were flooded out and carp swam along side the trucks that braved the high water. To handle these swells the city installed large additional pumps to help take the overflow but the frontline small gas pumps were usually the main resource.

The Pumps

City staff and management worked tirelessly around the clock to keep the water ‘at bay’ by pumping out areas of high risk for flooding. In most cases, the portable pumps required gasoline to run and the small tank meant that each had to be refilled or topped up every few hours – 24 hours a day, seven days a week!

Parks staff were stellar in recharging the fuel tanks and maintaining the fleet. It’s staggering to think of the work needed and the logistics required especially considering the environment and the scale of the site. It is after all, a loosely connected collection of islands; nothing more than a shifting sand bar really.

These pumps are gasoline engines with hoses to move water. They do not have or need an electrical source and they are about as analog a system as one could imagine. It’s just a very simple engine. It’s also very rugged and must endure harsh conditions in wet and muddy environments.

The Internet Of things…

It seemed there should be ways of helping Parks staff to manage the fleet of portable gas pumps using IoT technology; little devices that connect to the Internet and that can transmit/receive data.

The simple idea was to create a small unit that could be attached to a gas pump with a sensor of some kind, built-in perhaps, which could detect whether the engine was running or had stopped. It would then transfer that data periodically to a web site which could be securely shared with staff using mobile devices. In addition, alerts could be sent through text messages or email warnings when a pump stops working.

Because the pumps could be in remote locations throughout the park far from wi-fi access, the unit would ideally link to the network via a cellular connection. An onboard GPS would provide unit tracking and make management of pumps easier. The system would also need to be self-powered using a battery recharged by a small solar panel.

Oh, and it’s gotta be cheap!

Island Pump Monitors

Given the challenge above, the Island App Factory created and installed “Island Pump Monitors” on several engines to keep track of their progress and test the basic idea.

The red light indicates the pump is running.

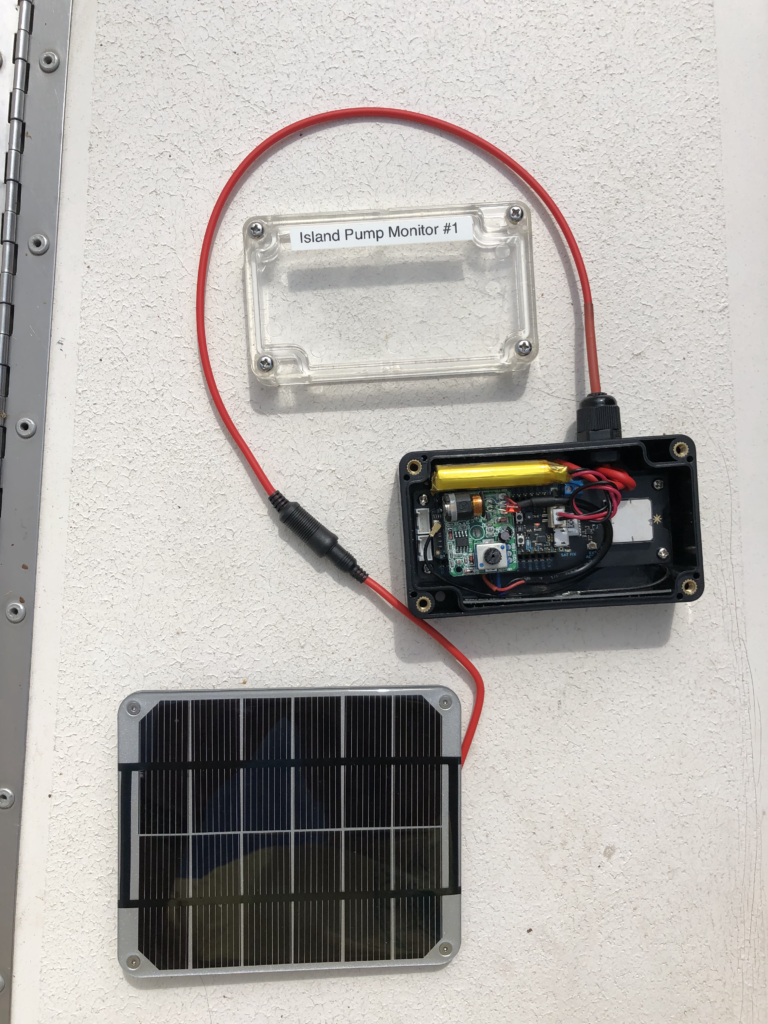

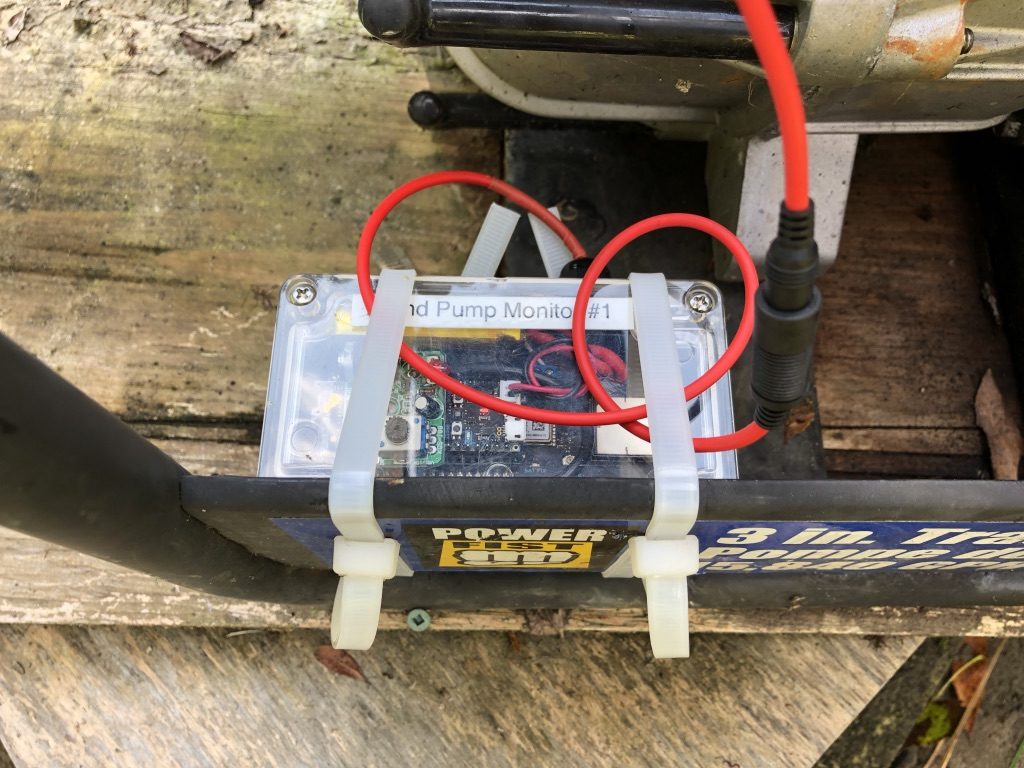

The monitors come in two different styles of sensors; built-in or external. The built-in sensor requires the main unit to be attached to the pump directly whereas the external sensor has a 12″ lead that allows the main unit to be installed beside the pump to reduce vibration.

Attached to the main unit is a watertight power connection for a solar panel which is paired with each device. The small durable panel recharges an onboard battery and if provided with reasonable access to outdoor sunlight can keep the device running indefinitely.

Each device has a GPS antenna to pin-point it’s location and each has a SIM card for 3G cellular data connectivity. The unit is sealed in a water tight plastic case with water tight ports for power and sensor wires.

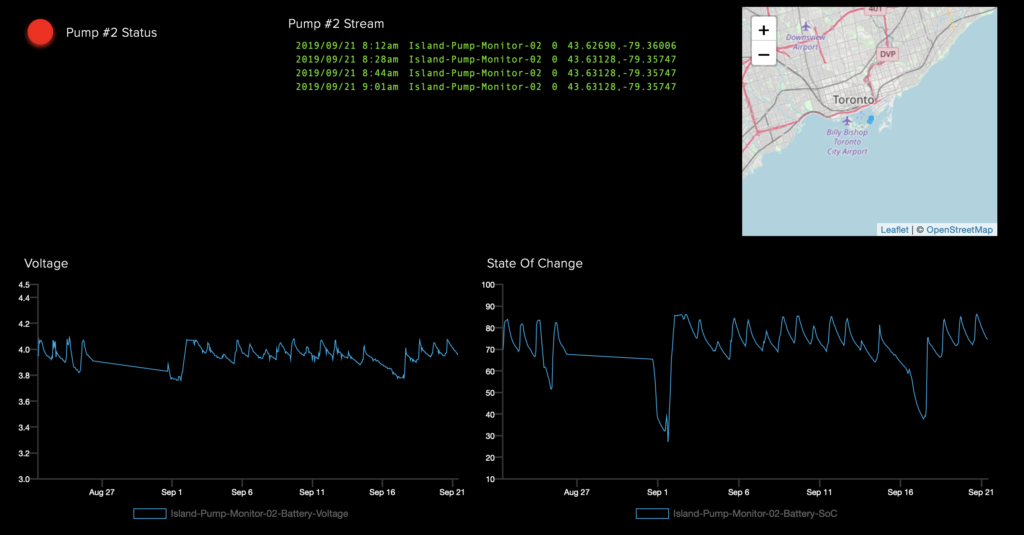

Every 15 minutes, each pump monitor checks the sensors and reports back its GPS location, Battery Voltage and State and of course whether the pump is vibrating and is therefore running. That data is fed to a ‘back-end’ server that then feeds that information to a web site where the information can be viewed and analysed.

(On/Off Status, Map Location, Voltage & State Of Charge)

Now again in English… Every 15 minutes the pump monitor wakes up and checks to see if it’s jiggling. After two minutes, it calls home and reports a simple sentence that tells us whether it’s running, where it is, and how it’s generally doing. Then it goes to sleep and waits until it’s time to repeat. The sensor sentence is parsed and displayed on a fancy graph. If there’s a warning state, the server will send out an alert by email or text message or both.

Mounting the monitors onto the pump itself was a big concern. I went through a dozen iterations in my head and on paper. After trying a variety of secure U-bolts, the best solution became industrial strength zip ties. These allowed me too easily and quickly attach and detach the unit and the solar panel; zip ties were well suited to the round tubing of the pump frame.

The Results…

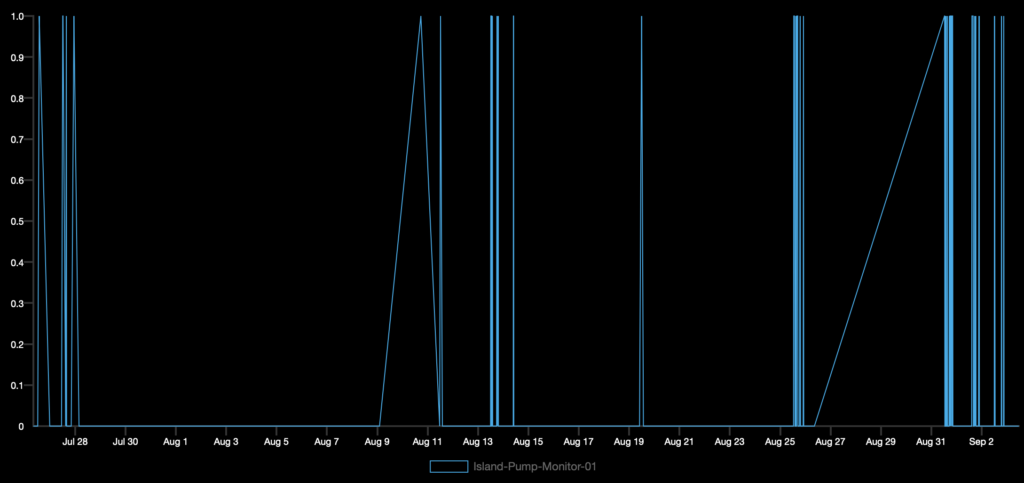

After several months of testing and running in the real world the results are in. The units ran from mid June until Sept 3rd, 2019. They collected three kinds of data: pump state, GPS location and battery condition.

The GPS was fairly accurate; its data displayed on a live Google map pin pointing the unit’s location every 15 minutes. Interestingly, once the flood waters subsided and the pumps were being shifted back to the depot, I was able to track the units across the island by their GPS location on a map and retrieve them! In real time more or less, I watched the one unit travel across the island and end up in a warehouse where it was removed from the pump.

The battery was continuously recharged during the day by the solar panel. Apart for cloudy days or locations that were covered by trees, the solar panels were very efficient. Each unit is paired with an appropriate sized panel. The panels were selected to provide the best output for price and each were durable and weather resistant.

The most important bit of data of course is whether the pumps were running or not: the ‘Pump State’. Over the course of two and a half months the pump monitors spit out the answer to the question, “Am I jiggling?” The real world results indicated the pumps tested were running 90-95% of the time! In fact it was so rare for a pump to go off that when one did one afternoon, I raced over to see why the device had failed only to discover the pump had run out gas — the system worked!

Now I chose pumps that were close to my house. Those pumps were always reliable. Pumps located in other locations were subject to more failures. One pump along Bayview Ave was always shutting down for a variety of reasons; that pump was critical because it was the only line of defence for homes only a few feet from the waters edge. I did test the unit on the Bayview pump for 5 days until a failure of the sensor caused by extreme jiggling halted the data. I knew about the failure within the half hour via email and contacted a local resident to check; even in failure the system worked!

The Cost?

Each Pump Monitor was priced at under $300. I have also created a Pump Monitor Pro version at just under $500.

Each Pump Monitor device requires a monthly cell data charge; roughly $4 – $6 but there is no contract and each unit can be managed using a web Dashboard. While I chose mostly free open source platforms for this testing, there are advanced services that will provide email, text messages and data display for an additional charge.

Considering the cost of the gas pumps and the cost of staff refilling and maintaining them, time saved by knowing the state and location of each pump seems a compelling return on investment.

What’s Next?

The results indicate that if/when the next flood happens, we have the IoT technology for managing the resources needed to combat the high water. Across a large area, we were able to monitor and track each unit using a mobile device and receiving alerts and status messages. That data shared in real time with Parks Staff charged with maintaining the pumps was arguably a useful tool in managing refills and pump failures.

An important benefit of this technology is that each Pump Monitor can be repurposed to serve other functions. Sensors can be attached for a variety of data gathering. While not performing flood duty, the units could be attached to Parks vehicles to track location and usage. The IoT is a flexible technology!

Thanks…

Thanks in large part to Joe Padovani and Warren Hoselton in the Toronto Parks Department. Their ability to see value in future technologies made the project a truly valuable investment. The Parks staff were also helpful and receptive to any idea that could help them manage a seemingly impossible task – to keep the lake from swallowing the Toronto Island.

In developing this project I relied heavily on the help of Particle.io. Their extensive line of networking products are brilliantly designed to make IoT an organic experience at an affordable price. Also thanks to Adafruit for their amazing boards and accessories and their stylish Adafruit.io web experience.